crushing process We are the world’s leading supplier of both unit machines and complete aggregates processing systems Comprehensive process solutions Your system may2011年10月24日· Inpit crushing and conveying (IPCC) is an alternative transport system which requires a higher initial investment but gives(PDF) Review of the inpit crushing and conveying

A system that allows repeatable, linear time ramp during startup and can balance load distribution during operation (regardless of load) offers the most protection for your2021年9月22日· The paper discusses the use of high speed, sideslewable belt conveyors in largescale surface mining, in conjunction with inpit crushing(PDF) OVERWIEW OF INPIT CRUSHING & CONVEYING

2020年9月1日· Inpit crushing and conveying (IPCC) systems (whether fixed, mobile, or semimobile) are an alternative to the traditional truck/shovel approach to materialsConveyor system The conveyor system transports the crushed material to the dumping site or the processing plant Conveyors can be designed stationary, relocatable orcrushing and conveying systems

also be used for crushing materials for the site’s infrastructure, roads, dams and underground backfill 312 Perth, WA, 20 22 August 2007 Iron Ore Conference J2019年1月18日· The present paper aims to provide a comprehensive literature review of all aspects of technical, economic and sustainable development of inpit crushing systemsInpit crushing and conveying technology in openpit mining

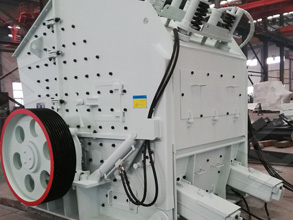

2021年4月13日· This paper investigates the longterm production scheduling and the crusher relocation plan of openpit mines using a semimobile IPCC system and highangle conveyor A series of candidatemethod The crushing plant can be either stationary, semimobile (transportable by means of transport crawlers) or of mobile type on crawlers Semimobile crushing plants can be fed either directly or by apron feeder Via discharge conveyor the crushed product will be transported to the conveyor system Conveyor systemcrushing and conveying systems ThyssenKrupp

Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining & Metals , Vancouver, BC Example: 60” x 89” primary crusher & mill feed conveyor system Operating schedule calculation for 3 x 8 hours per shift Days per year 365 Tonnes per year 32,850,年1月18日· Request PDF | Inpit crushing and conveying technology in openpit mining operations: a literature review and research agenda | InPit Crushing and Conveying (IPCC) systems are receiving moreInpit crushing and conveying technology in openpit

bility necessary for crushing extrahard materials while ensuring low maintenance costs 9 MCS 900 MCS 1150 MCH 900 MCH 1150 Max feeding size (mm) 100150 250400 4560 70175 Closed Size Setting (mm) 2544 2448 1032 844 Capacity (tph) 100200 180325 50140 90190 Power (kW/rpm) 75Joy feederbreakers and sizers are utilized to process material in the pit HAC systems elevate material from the pit on to overland conveyors for processing A HAC system can convey material at very steep angles, high lifts and capacities over 8,000 MTPH, saving up to 50% in material handling costsJoy Crushing and Conveying Systems Continental Global

2015年6月3日· PDF | Best Practices in Conveyor Safety is an Englishlanguage version of "Sécurité des convoyeurs à courroie Injuries result from shearing and crushing between the load and a fixedDo more with less go gearless Mine operators are challenged with moving more material on conveyors that may cover distances in the tens of kilometers and ascend steep gradients To increase overall reliability, mining companies also want fewer transfer stations between conveyors, which may require wider and longer beltsGearless conveyor drives Crushing and conveying | ABB

2019年11月6日· Abstract The automatic coal crushing system prototype system includes the design and construction of a PLC based coal crushing and conveyor system with HC12 module for wireless communicationPDF | On Jan 1, 2011, Mohammad Reza Tavakoli Mohammadi published Review of inpit crushing and conveying Conveyor transport requires a smaller size distri bution than truck haulage(PDF) Review of inpit crushing and conveying (IPCC) system and its

2017年3月4日· The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that theThe conveyor belts run true and centred The conveyor belt has not been damaged by tramp material like scrap metal, pipes and iron bars No potential dangers exist like large lumps of material sitting on structures and, partially torn belts flapping about All guards are in place and secureSAFE OPERATION OF CONVEYOR BELTS Rio Tinto

2021年9月22日· Semi fixed conveyor belt Finally, fixed conveyor belts are types of conveyors which should not be relocated along with the mine's life It is typically installed outside the pit and works with a2012年10月1日· The PF300 is a completely new fullymobile crushing plant with unique and compact design for onface mining applications which can be equipped with differentPF300 Essential part of INPIT CRUSHING and CONVEYING (IPCC)

PDF | On Oct 20, 2017, Manoj M Nehete and others published Design and Fabrication of PLC Based Conveyor System with Programmable Stations | Find, read and cite all the research you need on100 PLANT MAINTENANCE Clear effective isolation and lockout procedures are essential Premature or unplanned start up has caused many accidents in crushing and screening plants Refer to “Guideline for the Preparation of Isolation and Lockout Procedures in Mines, Quarries and Tunnels”Guidelines for Management Crushing and Screening final feb10

conveyors on boom conveyor and while in reclaim mode, boom conveyor discharges coal on the yard conveyor for feeding coal to bunkers through conveyors and transfer points The yard conveyor can be reversible type depending on layout requirement Figure 2: Coal Crushing System Coal Crushing Mechanism Three stage crushing system is used in2021年4月13日· Inpit crushing and conveying (IPCC) systems have drawn attention to the modern mining industry due to the numerous benefits than conventional truckandshovel systems However, the implementation of the IPCC system can reduce mining flexibility and introduce additional mining sequence requirements This paper investigates the longMining | Free FullText | A Framework for OpenPit Mine

Our customers benefit from a groundbreaking combination of services from engineering to recycling and digital conveyor monitoring, supplemented by more than 150 years of product and material expertise Making sure our customers can concentrate on their core business, is our core business Together, we are the Future of Conveying“Truck and Shovel Versus InPit Conveyor Systems: A Comparison of the Valuable Operating Time” In Proceedings of The Coal Operators’ Conference, 463–476Wollongong, Australia: The University of Wollongong Printery Paricheh, M, M Osanloo 2018 “How to Exit Conveyor From an OpenPit Mine: A Theoretical Approach”(PDF) Concurrent openpit mine production and inpit crushing

2019年1月18日· InPit Crushing and Conveying (IPCC) systems are receiving more attention today due to current characteristics of openpit mining operations and what is expected to occur in the future IPCC’s plan for waste material and optimum conveyor exit scheme are introduced as the main open problems that are worthy of future study2020年9月1日· Section snippets INTRODUCTION With the trend of open pits becoming broader and more profound in scale continuing, the potential of InPit Crusher and Conveyor (IPCC) systems to save costs deserves new tools to make the study of its practical comparison against more traditional truck/shovel systems more accessible andComparison of fixed and mobile inpit crushing and conveying

method The crushing plant can be either stationary, semimobile (transportable by means of transport crawlers) or of mobile type on crawlers Semimobile crushing plants can be fed either directly or by apron feeder Via discharge conveyor the crushed product will be transported to the conveyor system Conveyor systemCrushing and Screening Handbook is a dive into the world of rock processing and aggregates production It goes through the main factors impacting the quality and costs of aggregates, introduces differentCrushing and Screening Handbook minevik

Discover our durable crushers on our landing page: wwwcrushingtechnologies The TITAN® DoubleShaft Hammer Crusher is used for crushing mediumhard rock For wet limestone, wet marl, clay, chalk, gypsum and similar raw materials The mammut® crusher is uncomplicated and compact in design, rugged in its construction, extremely powerfulVarious types of crusher available for crushing like jaw crusher, gyratory crusher, cone crusher, Impact crusher, Double roll crusher, pulverizers, ring granulators etc The crushed coal is transported from crusher to thermal power plant through conveyor belt and is used in boiler The type of conveyors used for transferring the coal are listedCoal Crushing and Conveyer System Research Publish

Mass balance control of crushing circuits2021年4月13日· PDF | Inpit crushing and conveying (IPCC) Each conveyor scheme is considered a scenario for later calculation The study aims to develop, implement,(PDF) A Framework for OpenPit Mine Production ResearchGate

Safe Operation and Use of Mobile Jaw Crushers Free download as Word Doc (doc), PDF File (pdf), Text File (txt) or read online for free Mobile crushers are used in quarrying, ore processing and recycling of demolition waste This guidance covers the safe operation of the mobile crushing operation It includes guidance on Clearing Blocked crushers2020年9月1日· For the semimobile IPCC system, the crusher and conveyor are moved, as mentioned, every three benches lower into the mine, to within 100 meters of the ramp of any given placement Trucks with loads designated as waste are programmed to travel to the dump, located roughly 500 meters from the top of the ramp to the surface,Comparison of fixed and mobile inpit crushing and conveying

crushing system capabilities equipment, whether it is our gyratory or cone crushers, Ludowici screens or feeders, has continuously withstood the harshest requirements found in the world’s mines and rock quarries for over a century Our equipment delivers the rugged dependability needed to keep your plant running whileThis is mainly due to a number of sharp metals or objects, which Field monitoring and performance evaluation of crushing plant operation 625 are directly dropped on the conveyor by causing damages To prevent(PDF) Field monitoring and performance evaluation

NORDBERG LT105 industrial equipment pdf manual download Also for: lt105s Sign In Upload which is intented to be used in recycling minevik Minerals crushing applications in Feeder 9 Side conveyor / hand valves 10 Side conveyor turning, up/down Figure 39 Hydraulic valve location 02/02 338B NORDBERG LT105/105S2017年4月11日· WORKING OF IN PIT CRUSHER CONVEYOR SYSTEMS The opencast mining system adopted in RG OCII is "Inpit Crusher conveyor technology” ie, crushing of overburden and coal inside theIn pit crusher conveyour system | PDF SlideShare

Risk assessment Rock crusher Read online for freeSD Crushing” is used to reset the safety device system Tag list indicates all condition of the component, the value of start/stop crushing, reset SD crushing, motor conveyor, motor crusher and motor feeder C Crushing and BLC System Function Testing Testing the function of the crushing system is carriedThe Integration of Supervisory Control and Data Acquisition

2 Belt Conveyors 15 21 Applications 15 22 Conveyor nomenclature and arrangement 21 23 Effect of material characteristics on belt conveyor 22 24 Capacity 22 25 Belt conveyor idlers 26 26 Belt tension, power, and drive engineering 28 27 Belt selection 38 28 Relative advantages and disadvantages of hot vulcanized,GCDs: the power behind the world’s largest openpit copper mine Global Mining Review (English pdf Article) Extracting Potential with Gearless Mill Drives and Gearless Conveyor Drives Global Mining Review May/June 2020 (English pdf Article) Conveyors: durable and continuous (English pdf Article)Gearless conveyor drives (GCD) for medium power | ABB

Abstract A minimal residual oil content in the meal coming out of the hexane extractor is a clear benefit for a crushing plant; the more oil yield the better revenue for the crusher In a modern and ef cient extraction fi plant, a residual oil content 05% for soybean meal is2021年2月1日· Request PDF | Determination of Determination of semimobile inpit crushing and conveying The conveyors achieved an average of 3,509 hours in Valuable Operating Time compared to theDetermination of semimobile inpit crushing and conveying

Conveyors, we have the expertise to ensure you get precisely the right conveyor for your conveyance needs Conveyors, cranked conveyors and picking line conveyors Home; all new equipment is backed up by Crushing and Screenings own manufacturers guarantee Please call +44 (0)1845 to discuss your requirements in more detail