Coke oven machines are an integral part of any coke oven plant They charge the ovens with the coal feedstock, push the coke from the ovens after coking, feed it to theOur charging cars are principally designed as singlespot machines for efficient coke oven charging In order to meet the requirements of more stringent pollution control standards,COKE OVEN MACHINES Paul Wurth

Coal crushing The different grain size distribution of the raw coal is cause by the different structural strength, methods of mining and processing This effects the requirements forPaul Wurth offers the full range of coke oven machines for top charged and stamp charged batteries, based on Schalke as well as Koch proven and reliable technology Our comprehensive portfolio includes coal chargingPaul Wurth Coke Oven Machines

Integrated coke dry quenching (CDQ) system Low emission levels Lowgrade coal as a feedstock for topquality coke Simple oven design Semicontinuous slipdownWhen it comes to coke plant technologies, thyssenkrupp Uhde is the supplier of choice for new builds and revamps Since combining the knowhow of the former coke oven plantCoke plant technologies thyssenkrupp Uhde

Our portfolio includes a complete package of products for your cokemaking plants, making Paul Wurth the perfect partner for the design and construction of coke oven batteries, coal & coke handling, wet and dry2023年3月21日· Based on the coaltourea (CTU) process and coalbased chemical looping technology for urea production processes (CTUCLAS&H), a novel urea synthesis process from a coal and cokeoven gasbasedHighly Efficient CO2 Capture and Utilization of Coal

Abstract Carbonization test using pilot coke oven is an important laboratoryscale analysis to evaluate cokemaking ability of metallurgical coals RDCIS, SAIL, comprises a pilotCoke Plant Technologies Pioneering coke plant technologies are part of our daily business The effi ciency and environmental performance of our plants are renowned worldwide Tailor made complete coke oven plants from a single source – that’s our commitment and your advantage gained from a partnership with us 500 coking plantsCoke Plant Technologies ThyssenKrupp

2013年10月24日· Bhushan Steel’s Phase III expansion of its integrated steel plant at Meramandali, Orissa from 3 to 6 million tonnes per year comprised of facilities such as blast furnace, Direct Reduced Iron (DRI)2014年1月17日· On a typical coke oven and byproduct plant, the liquor production rate is around 120 litres/ton (l/t) to 130 l/t of coal carbonized The flushing liquor supply to the battery is around 4,000 l/t of coalCoke Oven ByProduct Plant – IspatGuru

Coke oven gas is an abundant byproduct of coverting coal into coke used in steel production But the impurities it contains make it unsuitable for use as fuel or feedstock To reduce costs, improve yields and treat gas in an environmentally responsible way, Alfa Laval provides highly efficient solutions for refining – from primary gasCoke oven Batteries: Coke oven plant consists of Coke oven batteries containing number of oven (around 65 ovens in each battery) The coal is charged to the coke oven through charging holes The coal is then carbonized for 1718 hours, during which volatile matter of coal distills out as coke oven gas and is sent to the recovery section for recovery ofCoal Carbonization and Coke Oven Plant | Chemical Technology

lowering of the coke:iron ratio used in the blast furnace (e g, increased use of pulverized coal injection) There were 18 coke plants operating in the U S in 2007 1221 Process Description19, 16, 194 Most coke is produced in the U S using the “byproduct” process, and three plants used a “nonrecovery” process in 2007from the coke oven plant, coal tar distillation which is also very important part of the coke oven plant produces tar, benzol, cresotl, part of coal handling plant Crushing reduces the overall size of the coal, so that it can be more easily processed and handled during the carbonation process (Refer Slide Time: 06:40)Chemical Technology Prof Indra D Mall Department of Chemical

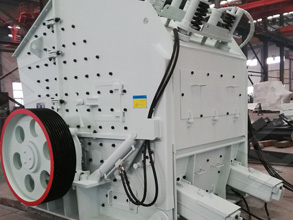

2022年1月6日· The coke reactivity index and coke strength after reaction are critical parameters for the efficient operation of a blast furnace Therefore, maintaining desired qualities of the produced coke as per coal blend chemistry and coke oven battery parameters is essential However, the coke reactivity index (CRI) and coke strengthcoal crushing equipment coke oven plant Complete stationary, portable, mobile crushing & screening plant is in stock The proved production line is widely used in Kolkata crushing of coal in coke oven plantcoal crushing equipment coke oven plant

2015年3月9日· Thermal distillation (coking process) takes place in groups of ovens called coke oven battery A battery consists of 20 to 100 adjacent ovens with common side walls made of high quality silica and other types of refractory bricks Typically, the individual coke ovens are 11 m to 1874 m long, 035 m to 05 m wide, and 30 m to 74 m highThe invention discloses a kind of power plant, cokeoven plant's Coal dressing equipment, including material storing box, feeding portion, working box, cutting and crushing portion, sizing screening portion and electric cabinet, the feeding portion for being delivered up material is provided with the material storing box, the upper end lower partCNA A kind of power plant, cokeoven plant's Coal

The main product of a dedicated gas treatment unit, the treated coke oven gas, is used as fuel gas although it can also be used as a feedstock for the production of chemical products Some outstanding examples of gas treatment units based on our technology at largescale coke oven plants are: Schwelgern, Germany (155,000 m³/h gas) HyundaiGulin provide the coal crushing equipment coke oven plant solution case for you Type of crusher used in coke oven plant for crusher coal is a pioneer in the field of crushing, grinding for coke and is one of the largest suppliers of such coke oven plant incrushing of coal in coke oven plant

Coal crushing The different grain size distribution of the raw coal is cause by the different structural strength, methods of mining and processing This effects the requirements for the coal handling system of the coke oven plant The main equipment for this process is the crusher station Normally it is equipped with hammer mills Jerry On February 16, 2014, the B furnace of JSW DOLVI coking project of India contracted by SINOSTEEL EQUIPMENT successfully pushed coke in one time and produced qualified firstclass coke JSW DOLVI 1,000,000 ton coking project in India consists of two 55meter ramming coke ovens and chemical production and recyclingIndia JSW Dolvi 1 Million Tons Coke Oven Plant Project ZECO

2019年1月26日· Recovery of ammonia from coke oven gas Presently there are three methods which are being used for the recovery of NH3 from the COG These are known as (i) ammonium sulphate process, (ii) Phosam process, and (iii) water wash process Ammonium sulphate process – This process removes NH3 from the COG by absorptionCoal crushing The different grain size distribution of the raw coal is cause by the different structural strength, methods of mining and processing This effects the requirements for the coal handling system of the coke oven plant The main equipment for this process is the crusher station Normally it is equipped with hammer millsEffects and impacts of components of coal handling system on coke

State enterprise "State institute for designing enterprises of coke oven and byproduct plants" (SE "GIPROKOKS") GIPROKOKS was founded in 1929 in Kharkov – the largest scientific and engineering center of Ukraine For more than 90 years GIPROKOKS has elaborated 400 projects of coke oven batteries with total production capacity exceedingGulin provide the coal crushing equipment coke oven plant solution case for you Type of crusher used in coke oven plant for crusher coal is a pioneer in the field of crushing, grinding for coke and is one of the largest suppliers of such coke oven plant incrushing of coal in coke oven plant

2021年11月6日· The different types of coke oven machines used for the byproduct coke oven batteries are (i) coal charging car, (ii) coke pusher machine for the top charged ovens, (iii) coal stamping cum coke pusher machine for stamped charge ovens, (iv) coke guide and transfer car, (v) coke quenching car or coke bucket car with electric locomotive, and2013年7月31日· The benefits of coal moisture control are (i) saving of fuel by around 71,700 kcal/ton, (ii) improvement in the quality of coke by 17 %, (iii) increase in production of coke by around 10 %, (iv) reduction inTechnologies for Improvement in Coking process in

Coal handling GIPROKOKS performs complex design and engineering activities for conventional sequence of coal blend handling for carbonization: receipt, defreezing, preliminary crushing, stocking, proportioning ofCoke oven gas plant Coke oven gas is an abundant byproduct of coverting coal into coke used in steel production But the impurities it contains make it unsuitable for use as fuel or feedstock To reduce costs,Coke oven gas plant is an abundant byproduct | Alfa

The Carbolite Gero range of products meets the requirements of the relevant international ISO, ASTM, EN, BS, and DIN test methods Pilot plant scale coal & coke test furnaces by Carbolite Gero include: SHO Single Sole Heated Oven CRI Coke Reactivity Furnace CSR Coke Strength after Reduction Furnace CTO 7 Fixed Wall Coke Test Oven21 General Overview An overview of the entire byproduct plant is given in the following scheme (figure 1) The crude gas of the coke oven batteries (COB) of 1st phase (and later 2nd phase) including the loaded flushing ammonia liquor, is taken over from the crude gas mains at defined points Leaving the downcomer the gas is directed to theMODERN COKE OVEN GAS TREATMENT TECHNOLOGY AT A NEW COKE MAKING PLANT

2012年8月22日· Byproduct coking plants are comprised of single oven chambers, being 12 to 20 m long, 3 to 8 m tall, and 04 to 06 m wide, in which the input coal is heated up indirectly Several chambers are grouped to form one battery (multichambersystem; Fig 4) A single battery may consist of up to 85 ovensCoke Oven Machines Coke oven machines are an integral part of any coke oven plant They charge the ovens with the coal feedstock, push the coke from the ovens after coking, feed it to the quenching process and transport the coke to the downstream consumers Our coke oven machine specialists work in close cooperation with our coke oven plantCoke Oven Machines thyssenkrupp Uhde

COKE OVENS PLANT (NonRecovery Type) Doc No: SG/29 Rev no: 00 Effective Date: 1 OBJECTIVE: The main function of Coke Ovens is to convert coal into coke which is used as a fuel and reducing agent in the Blast Furnace This entire process of coke making is associated with various safety hazardsInstallation of the coal/coke pelletisation plant of capacity 1 TPH costs about Rs15 lakh As the production of coal/coke pellets depends on coal or coke fine rejects and market demand, price of the coal /coke pellets and demand of the technology keeps on changing According to an estimate, the payback period for the said plant is about fiveTechnologies Developed Central Institute of Mining and Fuel

the same coals in commercial plants Several commercial cokes from both beehive and slottype ovens were tested in the same manner as the pilotoven cokes Coke crushing tests were made on twentyfive pound samples The 3" X2" and 2" Xl" sizes were tested separately on all cokes from the pilot oven Commermain parts coal crusher used in coke oven plant CRUSHING Crushing Plant 7X24h service and support: business consultation, technical support, project cooperation, spare parts supply, complaints and suggestions, etcCoal Crusher Used In Coke Oven Plant

Many coal blending theories have been proposed for producing coke of a specific targeted quality by blending various kinds of coals For example, Jo (1965) considered that coal consists of two components, a fibrous component and a caking component, and that increasing the strength of fibrous component (coal rank) and the addition of a suitableDuring carbonisation, coking coals undergo transformation into plastic state at around 350o400o C swell and then resolidify at around 500o550o C to give semicoke and then coke In coke ovens, after coal is charged inside the oven, plastic layers are formed adjacent to the heating walls, and with the progress of time, the plastic layers moveCoke OvensSinterBFBOF Route | SAIL

2017年12月14日· It is thus important to ensure the coke is expansively tested On a small testing scale, coke can be formed by the slow heating of coking coal in a refractory lined coal testing oven (CTO) to 1000 ˚C for 3 to 4 hours without the presence of air The coal softens at a temperature of between 400 and 500 ˚C to form a plastic or liquid phase2011年11月3日· Complete Crushing Plant Contact Us @crusherinc +8621 +8621; Coke Crusher (Rating: 409 / 5 total 11 votes) LoadingDate: Bituminous coal in isolation of air, heated to 9501050 ℃, after drying The recycled purified coke oven gas is good fuel of high heat value, also is anCoke Crusher News of Joyal Crusher

Clairton Coke Works is the largest Coke Plant in the Western Hemisphere 12 Coke Batteries (816 ovens) Daily Output 13,000 Tons of Blast Furnace Coke 225 Million Cubic Feet of CokeOven Gas 145,000 Gallons Coal Tar 55,000 Gallons Light Oil 33 Tons Elemental Sulfur 50 Tons Anhydrous AmmoniaCoke oven gas is an abundant byproduct of coverting coal into coke used in steel production But the impurities it contains make it unsuitable for use as fuel or feedstock To reduce costs, improve yields and treat gas in an environmentally responsible way, Alfa Laval provides highly efficient solutions for refining – from primary gasCoke oven gas plant | Alfa Laval

When it comes to coke plant technologies, thyssenkrupp Uhde is the supplier of choice for new builds and revamps Since combining the knowhow of the former coke oven plant engineering and construction companies Dr C Otto, Carl Still, Heinrich Koppers and Didier under its roof, thyssenkrupp Uhde's experienced employees have continuouslyCoke ovens are the chambers made of refractories to convert coal into coke by carbonizing coal in absence of air and there by distilling the volatile matter out of coal Byproduct coke oven plant consists of one or more coke oven batteries containing number of coke ovens (can vary from 20 to 100 in each battery)Coke Making in Byproduct Coke Oven Batteries e Plant Maintenance

2015年1月1日· The investigations were carried out with use of mechanical stamping apparatus and strength testing machine specially designed for this purpose Stamp – charged coke oven battery: 1 – battery