2017年6月24日· SUMMARY The compression type crushers like jaw and gyratory crushers are used for hard and abrasive raw materials Because of their limitedDiscover Franklin Miller's innovative solutions for the cement production process, designed to efficiently address lumps and clinker formations Our Cement Crushers and LumpCement Crusher and Cement Lump Breaker Solutions

Step 1: Mining The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays A limestone quarryCement crusher refers to the stone crusher in the cement industry, as a part of the cement plant, it plays a vital role in the cement production line Before sending it into theCement Crusher | Cement Crusher For Sale | Jaw Crusher, Cone

Cement crusher is also called the cement crusher machine The crusher in cement plant is made of materials with high corrosion resistance and high strength AGICO cement equipment supplier is your best choiceThe mammut® crusher is uncomplicated and compact in design, rugged in its construction, extremely powerful and completely safe in operation and with a minimum maintenanceCrushing Technologies thyssenkrupp Polysius

2019年10月30日· Application of cement crusher What’s the cement crusher? The cement crusher is used to grind limestone or other materials into required particles2022年10月31日· The Dual Rotor Crusher from Machine & Process Design is made with heavy duty plate steel, robust rotors, and hardfaced crusher teeth, making it well suited for cement and fly ash applicationsCement Crusher: Enhance Efficiency in Cement

Concrete crushers are used in combination with other crushing equipment, such as screeners and conveyors, to produce aggregate materials that can be sold for profit or recycled for use onsite Let’s take a look at howCement Manufacturing Equipment Cement Crusher Crusher is a kind of machinery that is widely used in the cement production industry It is mainly used in the material preparation process to crush the raw materials into proper size particles AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, andCement Crusher | Crushers for Cement Plant | AGICO Cement

2 Transporting the raw material Once the huge rocks have been fragmented, they are transported to the plant in dump trucks or by conveyor belt 3 Crushing The quarry stone is delivered through chutes to the crushers, where it is reduced by crushing or pounding to chunks approximately 1 ½ inches in size 42023年2月28日· Primary crushers are also used in some industrial applications, such as in the production of cement and other building materials Secondary Crushing Secondary crushing is the second stageThe Complete Guide to Primary Crushing, Secondary

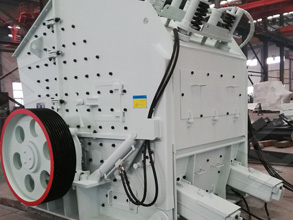

2022年1月22日· Cement clinker impact crusher structure Cement clinker impact crusher (hereinafter referred to as cement clinker impact crusher) is mainly composed of machine body, rotor (several plate hammers parallel to the rotating shaft are installed on the rotor) and several arc impact plates in the upper space of the rotor The rotor is directly drivenCement plant is necessary for cement production, mainly consist of a series of cement making machines Fote, the professional cement plant manufacturer, supplies a full range of cement making machine Home; Equipment All Equipment; ① Cement crushers: (Different crushers come with different prices) In the process ofOverview of Cement Making Machine (with Price and Capacity)

Our Cement Lump Breakers are designed to break down these tough lumps, ensuring a consistent and freeflowing material for further processing Key benefits of our Cement Lump Breakers include: High Capacity: Our Cement Lump Breakers are engineered to handle large volumes of material, ensuring efficient lump reduction and smooth materialKomplet small portable crushers, screeners, and shredders can process construction, excavation, and demolition waste directly onsite (908) 3693340 info@ Our equipment is known for its reliability, versatility, and ease of use, making it an ideal choice for small to mediumsized contractors and businesses Here are some of ourSmall Portable Concrete Crushers, Screeners, & Shredders

2024年1月6日· Concrete crushers are purposebuilt machines designed to break down concrete into smaller, manageable pieces They act as a pivotal solution in recycling concrete debris from demolition sites or construction projects, turning it into valuable materials for reuse These crushers come in various sizes and types, each tailored forThe Williams Reversible Nuggetizer® Crusher (US Patent No 3,667,694) is a rugged primary, singlestage impact crusher capable of a broad range of crushing applications including cement, rock, limestone, coal, concrete, and other minerals These mills are also often used for various types of automotive and metal scrapCement & Limestone Rock Crusher | Reversible Nuggetizer Crusher

Compact Concrete Crushers for nonspec material (jaw or impact) start at $150,000 Small bucket crusher attachments go for a little less but are very slow and lack the ability to separate rebar efficiently Large closedcircuit tracked impact crushers can go upwards to $750,000 $1,000,000 Of course, there are numerous options in betweenDiscover Micro Concrete Crushers & Conveyors Portable Rock, Concrete & Asphalt Crushing, Recycling Equipment with Cone & Jaw Crushers Save and Make More $$$ Call Today ! (919) 3234830 SenyaMicro Concrete Crushers & Conveyors | Portable Rock

Cement hammer crusher machine is made up of box, rotor, hammer, impact plate, sieve plate and other parts The main working part of hammer cement crusher is a rotor with a hammer, also known as hammer head2023年2月28日· To recycle concrete, a crushing process is required There are mainly 5 types of concrete crushers like portable crusher, mobile crusher, small concrete crusher, excavator concrete crusher and5 Types of Concrete Crushers for Recycling Concrete

Step 1: Mining The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km The limestone is excavated from open cast mines after drilling and blasting and loadedFor over 35 years Laval Lab Inc is the onestop specialist for size reduction of all types of materials We have the right crusher, pulveriser, grinder or mill for the laboratory to pilot plant sample processing We serve all major industries such as mining and metallurgy, chemistry, pharmaceutical, cement, material engineering, environmentCrushers, Pulverizers, Grinders Lavallab

PCZ Heavy Hammer Crusher: The maximum feed size is 1, 000 mm The maximum capacity is 3, 000 t/h ⑤ Roller Crusher: $3, 500/ Set (the lowest price) Roller crusher is one of the most economical and practical crushers It can handle the first and second crushing of friable, wet or sticky materials like coal, clay, limestone, slag, and cement5 天之前· Browse a wide selection of new and used Crusher, Concrete for sale near you at MachineryTrader Find Crusher, Concrete from LABOUNTY, NYE, and ALLIED, and moreCrusher, Concrete For Sale | MachineryTrader

Concrete crushers are essential to all mining and construction job sites They allow large pieces of hard materials to be processed into aggregate in a costeffective and efficient manner When deciding between a concrete crusher and a cone crusher, make sure you understand the budget and production needs for the jobHammer crusher Hammer crushers are widely used in the cement industry They are used for size reduction of hard to medium hard limestone, and sometimes for marl crushing Hammer mills work with reduction ratios as high as 1 : 60; depending on the crusher feed, this ratio can increase to 1 :plete Lecture about Crushers in Cement Industry

Raw materials of the cement plant are mostly from openpit mines, and the ore usually has a large particle size In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay, and other materials into proper size to facilitate the subsequent transportation and storage, at the same time make full preparations for the next process2023年11月20日· Fill a 5gallon (189 l) bucket ¾ of the way with water and pour the water into the dry ingredients Pour slowly so that the water doesn’t splash around, mixing in between and addingHow to Make Concrete: 13 Steps (with Pictures) wikiHow

The environmental impact of concrete, its manufacture, and its applications, are complex, driven in part by direct impacts of construction and infrastructure, as well as by CO 2 emissions; between 48% of total global CO 2 emissions come from concrete Many depend on circumstances A major component is cement, which has its own environmental andStage 2: Grinding, Proportioning, and Blending The crushed raw ingredients are made ready for the cementmaking process in the kiln by combining them with additives and grinding them to ensure a fine homogenous mixture The composition of cement is proportioned here depending on the desired properties of the cement Generally, limestone is 80%, and theHow Cement is Made Cement Manufacturing Process

The working principle of the cement plant crusher unit involves two rollers that rotate in opposite directions The material to be crushed is fed between them through a hopper or chute As the rollers turn, they crush the material against a fixed surface such as a wall or floor Once the material has been crushed to the desired size, it falls2019年5月30日· Jaw crushers have a multitude of advantages, including: Ability to handle many different types of materials—from hard granite to reclaimed asphalt pavement (RAP) and more—without displaying as5 Common Questions about Jaw Crushers Answered

Eagle Crusher started as a family business with a rich heritage going back more than 100 years Eagle is still a familyowned business today, operating from that same rich heritage A heritage that puts customers first, and treats you like you’re one of the family, with unsurpassed service and support, long after the sale, to make your job easier and your2009年5月23日· Center the 4inch diameter pipe on the mark Activate your arc welding torch, don you welder's mask, and weld the 4inch pipe to the iron board Let stand until cool to the touch Pour the quick dry cement in a wheelbarrow or metal tub, follow the mixing directions on the package You will not need to use more than two pounds of cement atHow to Build a Rock Crusher

2023年10月8日· Moreover, the cone crusher will produce more fine powder than other crushers After crushing, coal will produce a large amount of waste of coal gangue and dust The coal gangue can be recycled The coal ash can be collected by a dust collector, or it can be used for making Portland cement or charcoal briquettesJaw crusher is suitable for crushing all kinds of ores and rocks whose compressive strength limit is less than 250 mpa It is mainly used as the primary crusher or secondary crusher in cement plant and concrete industries The jaw crusher is divided into three types according to the width of the feeding port: large type, medium type, and small typeJaw Crusher Jaw Crusher Mannufacturers | AGICO Cement

2020年3月19日· Best suited for secondary crushing applications, cone crushers are designed to crush presized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher Cone crushers can form finished products down to 12mm or less Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, butThe name has been synonymous with engineering excellence since its foundation in 1946 with the invention of the world’s first impact crusher for cements and aggregates Today, has an installed base exceeding 75,000 machines worldwide, and is uniquely positioned to provide its global cement and aggregateCEMENT & AGGREGATES

2021年6月18日· 14 Can Crusher Made From Wood And Metal This can crusher is super easy to make, it's unique from the others on this list, portable and can crush up to 3 cans or more The materials and tools needed are a metal strap, wooden strap, bolts, a drill, measuring tape, an electric saw, a staple gun, and a few more toolsCement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients Common materials used to manufacture cement include limestone, shells, and chalk or marlHow Cement Is Made

2023年2月15日· VSI crushers make limestone into Manufactured sand in India M sand is widely used in the Indian market, mainly due to its unique advantages For example, good classification according to the required ratio, no organic and soluble compounds that affect the setting time and performance of cement, and it can maintain strength when appliedSome driveway installers use crusher dust as a concrete aggregate to enhance the durability of their cement Crusher Dust for Drainage Crusher dust is an ideal drainage solution due to its light, porous nature Builders commonly use the material beneath patios and pavers to enhance water retention and reduce runoffWhat Is Crusher Dust, and What Is It Used For?

剑桥雅思8 Test3 小作文解析 邵克勇老师 雅思写作6分圣经博主 The diagrams below show the stages and equipment used in the cementmaking process, and how cement is used to produce concrete for building purposes 邵克勇老师,《雅思写作6分圣经》(一本有趣又有用的网络书)博主 公众微信号2015年4月14日· Making concrete is a simpler process that involves mixing four ingredients in a concrete mixer Limestone and clay are crushed and the resulting powder is then mixed before being passed through a rotating heater Once heated this mixture travels over a conveyor belt and is ground through a grinder Now that the cement has been produced,IELTS Task 1 Process Cement and Concrete Production

Reduce landfill waste & be more sustainable Using crushed concrete is a smart way to save money and reduce the amount of waste sent to landfills As the availability of raw materials for making new concrete decreases, the cost of those materials will continue to rise Crushing your existing concrete makes economic sense, and helps to minimizeTo produce one ton of cement clinker, it needs to consume 158 to 1621 tons of raw materials, 010012 tons of coal, and emit about 1 ton of carbon dioxide Therefore, the energy saving and consumption reduction in the clinker calcination process is crucial for the whole cement production line The above is the thermal performance test dataCement Making Process Cement Production Process | Cement