Robust Reliable Crushing and sizing equipment that’s up to the task The demands on your crushing and sizing equipment are extreme Crunching up rock without breaking teeth Reducing sticky and soft materials without cloggingEvery material processing equipment has its crushers for material recovery crushers for material recovery is one of the products of Blue Group | , mobilecrushers for material recovery – Crushing and Screening Plant

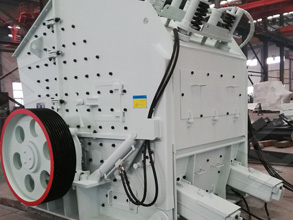

Crushers are machines used to reduce the size of rocks, stones and ore They are often utilized in aggregates production, construction material recycling and in miningThere are many different types of crusher, such as jaw, gyratory, cone (or disc) and impact crushers (Fig 159), each of which has various advantages and disadvantagesImpact Crusher an overview | ScienceDirect Topics

Equipped with a horizontal shaft impact crusher and a feed hopper with belt feeder, it is designed especially for processing soft and mediumhard materials, such as limestone and recycled materials They can be used2021年3月25日· Horizontal Shaft Impact Crushers, such as the New Holland, Andreas and MaxCap (which is a hybrid of the two) styles, are typically used for the primary size reduction of soft to medium hardMcLanahan | What Type of Crusher Is Best for Primary

With the ability to crush material with a feed size of up to 90 mm, our HSC590 Jaw Crusher is a real workhorse It crushes to a final fineness of < 4mm and with a gap width of 030Crushers are essential machines in several industries for particle size reduction They are invaluable in laboratories (higher institutions and research centres), the mining and constructionMaterial Mass Recovery and Crushing Time

Crushers and breakers are used to reduce size of mined and quarried material for further processing or to size suitable for the intended end use The goal of a crusher is to crushcrushers for material recovery regencypark Explore Our Products Here AFB has a full coverage of coarse crushing, intermediate crushing, fine crushing and sandmaking, sandwashing, feeding, sieving, conveying equipmentcrushers for material recovery

2023年8月31日· The can crushers are available for purchase We have researched hundreds of brands and picked the top brands of can crushers, including McKay, Pardecor, Mazeluxe, yamagahome, CGELE The seller of top 1 product has received honest feedback from 628 consumers with an average rating of 49Thanks to the optimised crusher speed and generously dimensioned fly wheels our Jaw Crusher EB series accounts for 25% lower energy cost compared to the competitors in the market Lower energy consumption Reinforced front and back wall Additional outer reinforcing ribs to coincide with the lines of force Swing jaws made of heavyduty materialsJaw crusher EB |

Both methods are in actual fact used for bulk material reduction and require a further process for the final diamond recovery SIC Code 3830, Materials recovery ~ recovery of materials from waste streams in the form of: ~ separating and sorting recoverable materials from nonhazardous waste streams () ~ separating and sorting of commingledThe purpose of this paper is to select a suitable candidate material for the design of crusher jaw that can sustain fracture by any of the three modes of failure – tear, shear and impact at low cost using CES EduPack Keywords Crusher jaw, Material selection, CES EduPack, Fracture, Comminution 1 Introduction of the final crusher productMaterial Selection for Crusher Jaw in a Jaw Crusher Equipment

2023年2月28日· Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes Each stage uses different types of crushers and has distinct advantages and disadvantages This article provides a comprehensive guide to primary, secondary, and tertiary crushingWith the ability to crush material with a feed size of up to 90 mm, our HSC590 Jaw Crusher is a real workhorse It crushes to a final fineness of < 4mm and with a gap width of 030 mm It can be operated in automatic, standalone, standalone with magazine, linear automation, and robot automation modes, introducing newfound flexibility to your processes and settingFine Jaw Crushers

Demand more from your minevik® MP™ crusher with our high performance spare parts and liners Our spare parts do more than replace the components in your minevik® cone crusher—they improve its performance Get a longer wear life, better efficiency, increased safety and more throughput with EXCEL™ replacement partsProduces more material of the desired cubicity and graduation than other crushers of the same size Flexible for multisite crushing, with a maximum diameter of 375 m (148 in) and weight of 50,274 kg (110,833 lbs)Raptor® Cone Crusher best in class |

Crushers — Wastech Engineeringsmall crusher for automobile alyst recovery motauvideocoza First the crusher is designed to destroy the integral shape of any loose material sheets or even pallets tearing it all to shreds The High Force Auger then compacts this treated material achieving up to double the bin weights when compared to Crushers For Material Recovery Felona Heavy Industries Crushers For Material Recovery Crushers for material recovery Stone Material Handling can deliver a variety of services and equipment to efficiently meet your needs whatever the commodity including material ground loss recovery dust control screeningcrushers for material recovery

The rotor centrifugal crusher of type RSMX is a highperformance crusher and is used to selectively crush and refine all types of minerals, from soft to hard and fragile to extremely abrasive Depending on its size, high throughput rates can be achieved Every single particle of the input material undergoes extreme acceleration due to theProgress in RollCrushing BY C Q Payne, New York, N Y On the right, a Roll Crushers is shown in a sectional elevation of the AC singleroll crusher while here below is a cutaway view of the machine, with hopperRoll Crushers Top 2022 Models 911 Metallurgist

HP Series cone crushers bring together the optimal combination of crusher speed, throw, crushing forces and cavity design As the name suggests, these proven and reliable universal crushers deliver High Performance in quarrying and mining applications They deliver predictable and consistent production, and they are troublefree, easy2016年2月26日· The difference between the cumulative percentages at the 35″ and 15″ points on the curve gives us the amount, of such product to be expected from the output of the primary crusher This is 85 minus 43, or 42% of the primary crusher product If our problem had covered a crushing condition calling for 80 instead of 85% passing theCrushing Products Size and Shape What to Expect 911

The 911MPELRC Laboratory Roll Crushers are typically applied in laboratory or pilot plant applications after primary reduction of the infeed material Roll crushers operate with a minimum of dust generation and produce a material with a tight size envelope containing a minimum of fines Designed for rapid, controlled size reduction of ore, mineral or rockCompression mining crushers solutions for breaking down hard minerals and ores Enjoy optimum performance and reduced cost with compression crusher equipment and products For over a century, has been renowned as the preferred crushing technology provider for mining and related pression mining crushers | Primary crushers |

2021年3月12日· Evolving accuracy in aggregate output size According to Norbert Dieplinger, Austriabased Mineral Processing's international business development manager, "Specs are getting tighter so crushers must be much more accurate than in the past For example, a few years back you could just crush aggregate down to 0 to 3inchVERSATILITY: The REBEL CRUSHER can tackle nearly ANY application; small, medium and large! It has the ability to prescreen, crush, and separate crushed material into three (3) separate stock piles while removing rebar, wire, and steel at the SAME TIME! Capable of tracking and crushing without stoppingThe Rebel Crusher Crush, Screen and Track RR Equipment

— Jaw crusher is a kind of size reduction machine that is wide utilized in mineral, aggregates and metallurgy fields The interaction between jaw plates and material particles brings the inevitable and high wear to the jaw plates throughout the jaw crusher operation, that not only decreases the efficiency, however also will increase the price and also the2016年10月23日· Crushers It is difficult to define exactly the meaning of the terms crushing and grinding, or crushing and pulverization; the finer crushing stages may embody a certain amount of pulverizing or grinding, but in the main, crushing may be said to cover the reduction of stones or ores to a size of ½ inch, and in some cases slightly lessCrushers 911 Metallurgist

Recovery area, like construction waste, slag and tailing after metal smelting, etc Crushers can be used to recover some useful materials from those “waste” and reduce environment pollution First, the feed material isCrushers thyssenkrupp offers a wide range of Crushers that are designed to take on any crushing job Different types of crushers are used for crushing different types of materials ranging from soft coal to very hard iron ore Each type of crusher comes in various sizes, with selection dependent on the requirement of particular capacity, feedCrushers thyssenkrupp Industries India

2024年1月17日· About This Product: Much like our top contender of the same brand, Dial Industries M92 Can Crusher offers the same 12ounce cancrushing experience, however, the builtin basket has the capacity to store 10 cans at once This indicates that it should be used for multicrushing cans Users can very quickly and easily crush up to 10 cans in 10Crushing and sizing equipment that’s up to the task The demands on your crushing and sizing equipment are extreme Crunching up rock without breaking teeth Reducing sticky and soft materials without clogging Your process depends on the ability of these machines to do their jobs – so we make it our job to provide crushing and sizingCrushing and sizing technology for all stages

Just call +903123979133 and we will help you in any way we can You can also send an email to sales@mekaglobal, or fill in the inquiry form if you would like to pass us a detailed inquiry or project information Use the Call Back option if you would like to be contacted by our sales team Primary Impact crushers have proven their2023年9月7日· 5 Provide a wellgraded feed Another best practice for feeding Jaw Crushers is to blend the feed material ahead of the crusher to ensure a wellgraded feed This will produce steady, consistent tons per hour out of the Jaw Crusher It will also promote interparticle crushing to break any flat or elongated materialMcLanahan | Best Practices for Feeding Jaw Crushers

Laboratory Crushers Laboratory grade crusher suitable for crushing Pharma wastes like vials, ampules,some organic material, blisters, foils with arrangement for liquid separation and dust collection A laboratory crusher, or pulverizer, is a device designed to forcefully reduce solid samples such as rocks to fine dust or powder for molecularThe Williams Reversible Nuggetizer® Impact Crusher (US Patent No 3,667,694) is also often used for various types of automotive and metal scrap Contact us today to discuss your application in detail with one of our experienced sales engineers Call (314) 6213348, us at info@williamscrusher or locate an agent near youImpact Crusher Machines | Williams Patent Crusher

All versions of our kubria® Cone Crushers ensure that the material has a long retention time in the crushing chamber, with a correspondingly high number of crushing steps As a result, the crusher produces a product of high cubicity, enabling you to meet the product standards required for concrete aggregate and other products2023年8月15日· Crushers vs Breakers: A Complete Guide for Choosing the Right Option August 15, 2023 Read this blog to learn how to choose between a crusher or breaker for your application Size reduction is the first step in many materials processing plants The goal with this step is to reduce large lumps of mined materials, be it rock or mineralMcLanahan | Crushers vs Breakers: A Complete Guide for

HP Series cone crushers bring together the optimal combination of crusher speed, throw, crushing forces and cavity design As the name suggests, these proven and reliable universal crushers deliver High Performance in quarrying and mining applications They deliver predictable and consistent production, and they are troublefree, easyK & M Krusher Rock/Ore Crusher 55HP Honda Gas Motor 14" Drum 3" InfeedRockwell #58 Hammers $1,949 1 2 3 Find rock crushers and mortars for prospecting online at High Plains Prospectors We supply treasure hunters with aRock Crushers & Mortars | Pneumatic Rock Crushers – High

We offer four Eccentric Roll Crusher ERC® types for various applications 1) Weights indicated do not include base frame, drive motor and tools Weights may vary depending on actual machine configuration 2) Motor rating range applicable for < 1,000m altitude Actual motor rating depending on the feed material characteristics, desired productSince 1991, RUBBLE MASTER has brought numerous innovations to the market We’re crushing & screening experts and work closely with contractors and aggregate producers worldwide Send us a message Stop wasting time and money on disposing of your materials Profitable and easytouse Compact Crushers for onsite concrete &The Best COMPACT CRUSHERS for OnSite Recycling | RUBBLE

2023年2月28日· Secondary crushing is the second stage of crushing that takes place after the primary crushing The secondary crusher is the equipment that reduces the size of the materials further, after they have been reduced by the primary crusher The secondary crusher has a size reduction ratio ranging from 3:1 to 5:1 The secondary crusher canREM® CAN CRUSHERS – MODEL HV PERF With a processing capacity of up to 20,000 containers per hour, the Model HV Perf Compactor is the full beverage destruction equipment you’ve been waiting for Designed to fill the need for a very high volume full beverage destruction system with the added benefit of absolutely no handling of theCAN CRUSHERS Compactors Inc

2020年12月17日· Jaw crushers can be divided into two basic types, single and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation, along with the toggle plate, causes a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the topOUR PRODUCTS Pilot Crushtec International (PTY) Ltd is South Africa’s leading supplier of a full range of heavyduty crushing, screening and materials handling products, parts and services Whether you’re looking for jaw crushers, cone crusher, screens, feeders, magnets, tower lights or conveyors, you’ll find the appropriate solution toJaw Crushers Cone Crushers Mining Equipment Pilot Crushtec